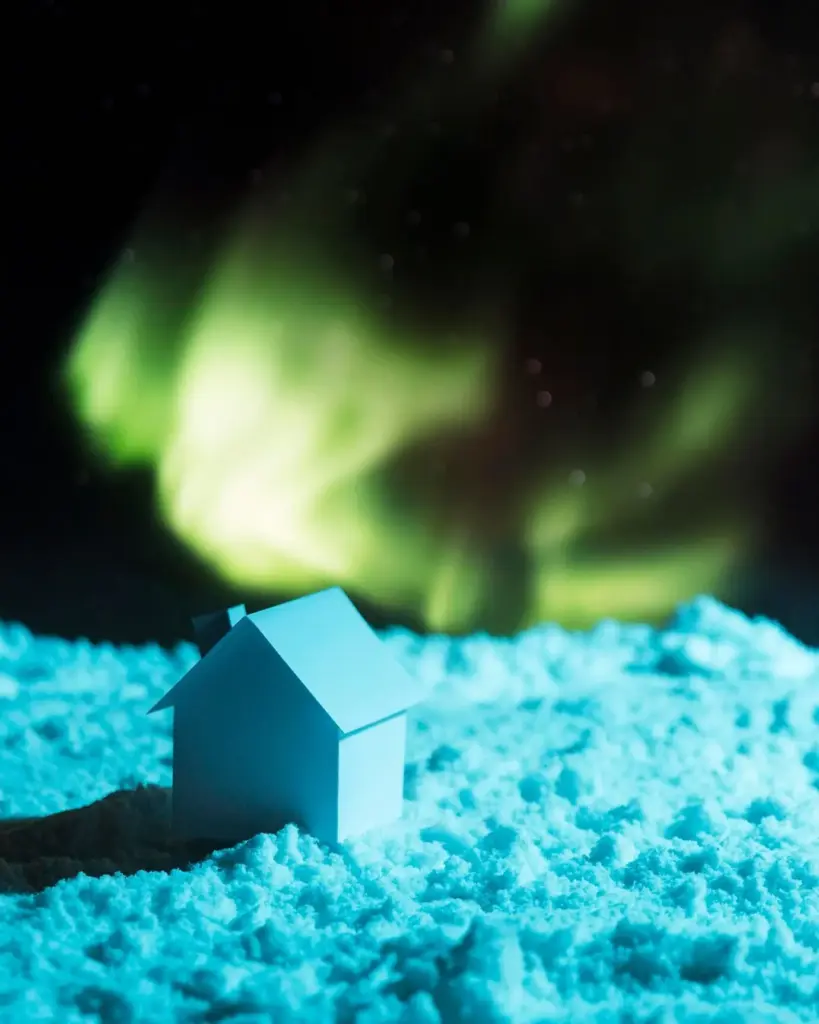

Smarter Choices for a Lower-Carbon Home

What Carbon-Sequestering Materials Actually Do

Upfront Price vs Lifetime Value

Where the money goes

Costs concentrate in materials, skilled labor, logistics, and details that control moisture and air leakage. A learning curve can raise bids when contractors are unfamiliar. As supply chains mature, premiums often narrow. Consider packaging measures—air sealing, exterior insulation, flashing upgrades—so the total assembly delivers stronger returns than any single product alone.

Stacking incentives and financing

Look for utility rebates, municipal grants, and green mortgage products that reward lower energy demand or verified carbon reductions. Some lenders value improved envelope resilience and durability. Bundling insulation, air sealing, and ventilation improvements can unlock better incentive tiers. Ask programs how they evaluate embodied impacts, not just operational savings, to recognize full benefits.

Performance, Comfort, and Everyday Living

Fire safety without compromise

Pests, mold, and the passage of time

Installation and Sourcing That Work

A cold-climate bungalow transformed

New build with hemp-lime walls

Biochar-enriched concrete on a slab project